With OPRA, we are not reinventing the wheel, but we are making it much more rounded. Many cumbersome SAP transactions become user-friendly and task-orientated processes that are precisely tailored to the needs of the respective end users thanks to the OPRAmobile and OPRAdesk applications. Different systems and data sources become a uniform and intuitive solution. Tedious activities become efficient actions. A jumble of data becomes a transparent and evaluable database. Everything SAP-based – without interfaces or middleware.

OPRA is based 100% on SAP technology, so it does not require any interfaces or middleware and therefore enables smooth interaction with other SAP modules such as MM, FI/CO, HR, SD etc. Furthermore, OPRA allows the seamless integration of non-SAP systems such as GIS, CAD, and spare parts catalogues.

Appealing, user-friendly and role-specific interfaces lead to a higher acceptance of the system among users, reduce the error rate through wizard-based user guidance and accelerate familiarisation. This leads to an increase in efficiency for the users and the system.

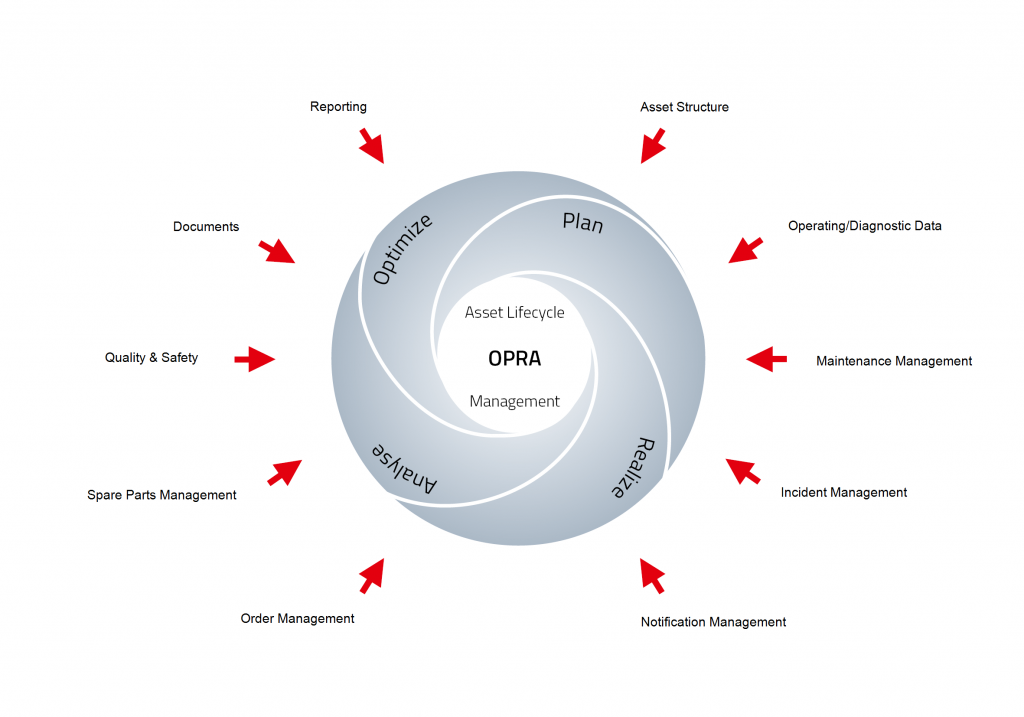

The most important processes for efficient maintenance or asset lifecycle management are already mapped in OPRA and only need to be extended by customer-specific requirements. This leads to a very quick and economical implementation of the solution if SAP PM/EAM is already in operation.

OPRA works in a process-oriented way. Only necessary data of the SAP transactions are recorded in the cockpits. They are automatically stored in the appropriate place in the database and relevant processing procedures are automatically executed in the background, even in non-SAP systems. The decisive advantage over a classic SAP PM/EAM application is therefore the increase in efficiency of the overall system and the individual users.

OPRA works in a process-oriented way. Only necessary data of the SAP transactions are recorded in the cockpits. They are automatically stored at the appropriate place in the database and relevant processing procedures are automatically executed in the background, even in non-SAP systems. The decisive advantage over a classic SAP PM/EAM application is therefore the increase in efficiency of the entire system and the individual users.

Failures can best be avoided if the corresponding signs are recognised early, and signals are sent to the SAP system. Together with you, we develop an individual concept of how sensor data is to be handled, when a fault message is automatically created and how it is to be prioritised. Within the framework of a workflow concept, it is possible to define ad hoc measures or to generate notifications (email, SMS, etc.). Maintenance becomes Maintenance 4.0.